Professional Tips on Implementing Foam Control in Chemical Processing Environments

Professional Tips on Implementing Foam Control in Chemical Processing Environments

Blog Article

The Role of Foam Control in Enhancing Item High Quality and Effectiveness

Foam control is an often-overlooked yet crucial element in the quest of product quality and functional effectiveness across diverse industries. By effectively taking care of foam development, business can not just improve the consistency of their formulations yet additionally deal with operational challenges that can restrain efficiency. This discussion will certainly check out the multifaceted impact of foam on both item honesty and production processes, elevating crucial inquiries concerning the techniques that can be used to maximize foam control. As we take into consideration these ramifications, it ends up being clear that the stakes are higher than they might originally appear.

Comprehending Foam Formation

Foam development is a complex sensation that can substantially influence product high quality and functional effectiveness throughout different sectors. Understanding these variables is critical for managing foam properly.

The liquid's thickness and surface tension play crucial roles in foam stability. Surfactants, as an example, can reduce surface area stress, promoting bubble formation however additionally enhancing foam stability, which can be bothersome in certain applications. Furthermore, mechanical frustration, temperature level fluctuations, and the existence of impurities can intensify foam generation, making it crucial to monitor these elements throughout manufacturing processes.

Industries such as food and drink, drugs, and chemical production have to be specifically watchful concerning foam control. By comprehending the hidden systems of foam development, organizations can carry out targeted approaches to mitigate its results, thereby preserving functional performance and making certain consistent product performance.

Influence On Product Top Quality

The visibility of foam can dramatically compromise product quality throughout numerous markets. In producing processes such as food and drink, drugs, and cosmetics, too much foam can cause inconsistent product solutions. In food production, foam may catch air, impacting texture and taste, which can eventually modify customer perception and satisfaction.

In addition, foam can impede the uniformity of paints and layers, causing problems like bubbles and uneven surfaces. In pharmaceutical applications, foam can interfere with the exact dosing of fluid medicines, potentially influencing restorative efficiency and individual safety. These top quality issues not just decrease completion product's allure but can additionally result in pricey recalls and damages to brand name credibility.

Additionally, the presence of foam can complicate top quality control steps, making it difficult to accomplish consistent outcomes and exact dimensions. Effective foam control not just mitigates these dangers yet also improves total product high quality by making certain that formulations satisfy rigorous industry requirements. By purchasing foam control strategies, companies can secure their items, enhance customer complete satisfaction, and keep an one-upmanship in the marketplace.

Operational Challenges From Foam

Efficient procedures in numerous sectors can be significantly interfered with by the visibility of foam, which presents numerous obstacles throughout production processes. Foam can hinder mixing and reaction times, hampering the efficiency of chemical processes. In industries such as food and beverage, foam formation can result in unreliable fill degrees, causing product waste over at this website and disparities in packaging.

In atmospheres where hygiene is vital, such as drugs and food handling, foam can complicate cleaning protocols, creating covert reservoirs for contaminants. This not only raises high quality issues however likewise can result in compliance issues with regulatory standards.

Additionally, the mental impact on operators can not be overlooked; excessive foam can develop a disorderly job atmosphere, causing decreased spirits and performance. In summary, resolving the operational challenges positioned by foam is important to preserving effectiveness and product top quality in numerous markets.

Techniques for Effective Foam Control

Exactly how can industries successfully minimize the difficulties posed by foam? Reliable foam control techniques are important for boosting product top quality and operational performance. One main approach is making use of defoamers, which are chemical agents created to eliminate or lower foam formation. Choosing the appropriate defoamer needs a comprehensive understanding of the certain process problems and the materials involved.

In enhancement to chemical remedies, process optimization plays a critical role in foam administration. Industries can analyze and adjust specifications such as blending click here to read temperature, speed, and stress to decrease foam generation. Implementing devices adjustments, like mounting foam-breaking tools or adjusting container view it now design, can even more help in reducing foam degrees.

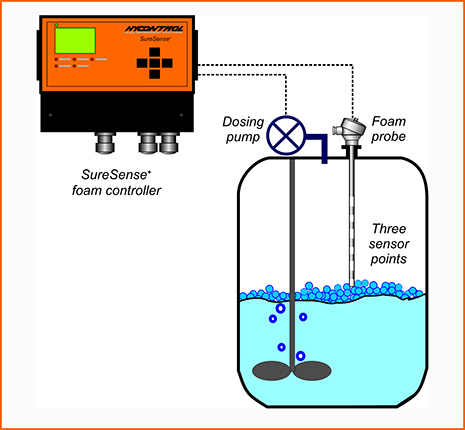

Normal surveillance and analysis of foam behavior within production procedures are also important. Using sophisticated sensors and analytics can offer real-time data, enabling timely interventions and modifications. Staff training is equally essential; guaranteeing that workers are well-informed regarding foam characteristics and control strategies can result in aggressive foam management.

Study and Market Applications

While lots of markets deal with distinct challenges connected to foam control, study disclose that customized techniques can substantially enhance both product top quality and functional efficiency. In the pharmaceutical sector, as an example, a leading maker executed a custom foam control approach that minimized foam formation throughout fermentation procedures. This innovation not just enhanced yield by 15% yet likewise minimized contamination threats, guaranteeing higher product honesty.

Likewise, in the food and beverage market, a major milk producer challenged too much foam throughout pasteurization - Foam Control. By introducing a specialized antifoam representative, they decreased handling time by 20%, which directly equated to increased throughput and minimized power usage. The application of foam control measures ensured constant item structure and preference, reinforcing brand name loyalty

In the chemical manufacturing market, a study highlighted the successful application of foam control in wastewater treatment procedures. The implementation of a real-time tracking system enabled operators to change antifoam dose dynamically, leading to a 30% decrease in chemical use and improved effluent high quality.

These study show the varied applications of foam control throughout industries, highlighting its critical function in boosting item top quality and operational performance.

Final Thought

In final thought, effective foam control is indispensable to boosting item high quality and operational efficiency across numerous sectors. Eventually, focusing on foam control contributes to improved productivity, guarding brand name track record, and enhancing customer contentment, highlighting its value in high quality assurance within making procedures.

Foam control is an often-overlooked yet important component in the search of product high quality and operational efficiency throughout diverse sectors. Personnel training is equally vital; making sure that personnel are educated regarding foam dynamics and control strategies can lead to proactive foam monitoring.

While lots of industries encounter unique obstacles associated to foam control, instance research studies disclose that tailored strategies can substantially enhance both product top quality and operational performance (Foam Control). In the pharmaceutical industry, for circumstances, a leading manufacturer carried out a custom foam control method that reduced foam formation throughout fermentation processes.In final thought, reliable foam control is essential to boosting product high quality and functional performance across different sectors

Report this page